Piece by Piece: Overhead Cranes Explained – Part 6 – Hoists

/ Blog

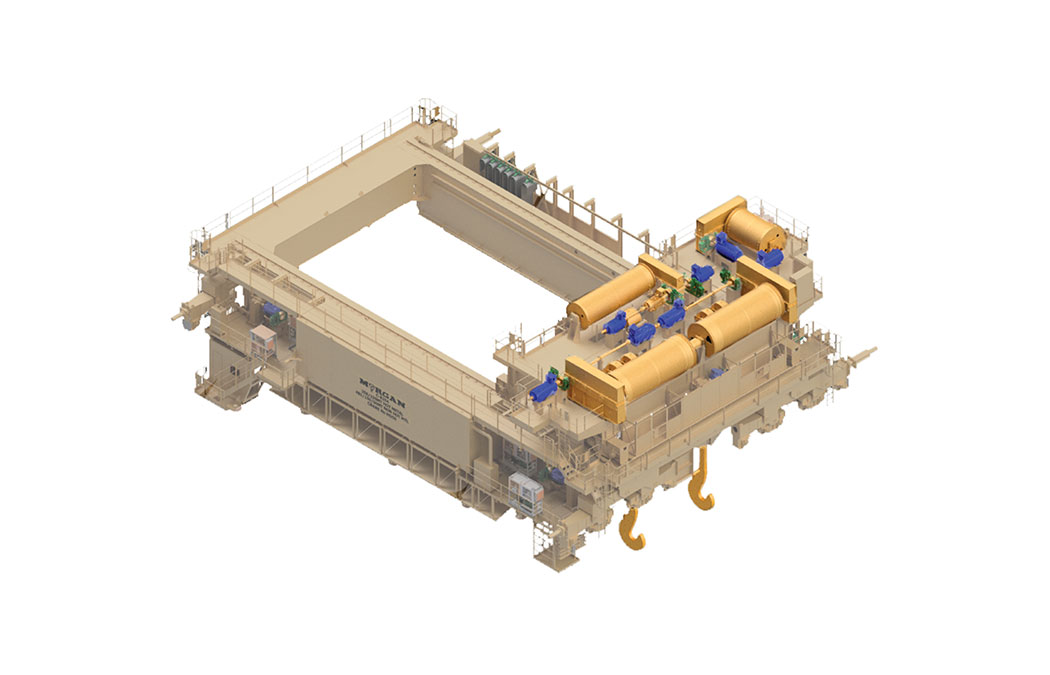

The overhead crane hoist allows a crane to complete its vertical motion and pick up loads of varying capacities. As a leading overhead crane manufacturer, we understand that not all jobs hoists are required to do are the same. That’s why we customize every aspect of our overhead cranes, including the device doing the lifting.

This is the last edition of our Piece by Piece series. If you haven’t read the previous five installments, begin with our first post, Piece by Piece – Overhead Cranes Explained – Part 1.

A Crane Hoist Defined

An overhead hoist is essential for lifting, lowering, and maneuvering loads with precision using an overhead crane. It is made up of a system of components that provide the vertical motion that is all mounted on the trolley, making it a critical part of the overhead hoist system. Every other section of a crane is made with the handling of the load in mind.

Digital rendering of a reeving system.

Reeving System

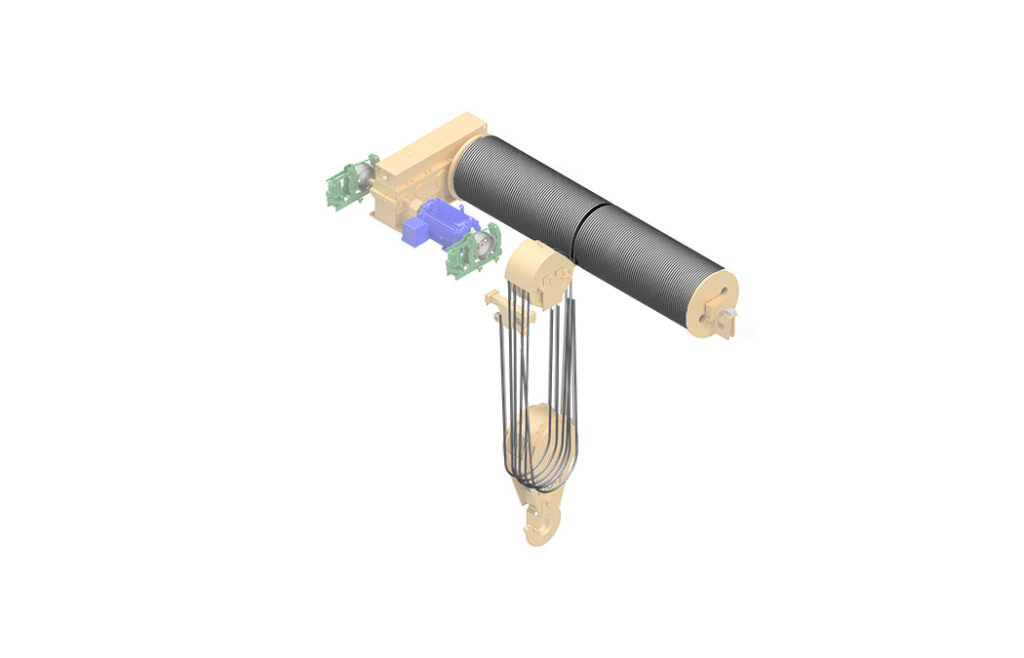

The reeving system of an overhead crane hoist includes the wire rope, drum, blocks, equalizer, and pulleys, all crucial in determining the speed and capacity of the overhead crane.

A digital rendering of the wire rope used with a hoist.

Wire Rope

The wire rope, which can also be a chain if applicable, serves as a connecting point between the fixed upper and moving lower systems. It wraps around the drum as the load lifts or unwinds from the drum as the load lowers.

The reeving system allows us to calculate the size of rope that we’ll need for the overhead hoist’s rated capacity.

Upper and Lower Sheaves

The upper and lower sheaves are grooved discs that rotate around a bearing or bushing on a pin and guide the wire rope. The upper sheave system is fixed to the trolley, while the lower sheaves are attached to the hook block or beam and move with the load. The number of upper and lower sheaves depends on the reeving system selected.

Here is a rendering of an equalizer/dead end.

Equalizer or Dead End

An equalizer, or dead end, is the termination point for the wire rope in an overhead crane hoist system. It is located opposite the drum and can be fixed to the trolley or the hook block. A dead end is used when a crane hoist utilizes a single rope. An equalizer is used when multiple ropes are introduced into a reeving system.

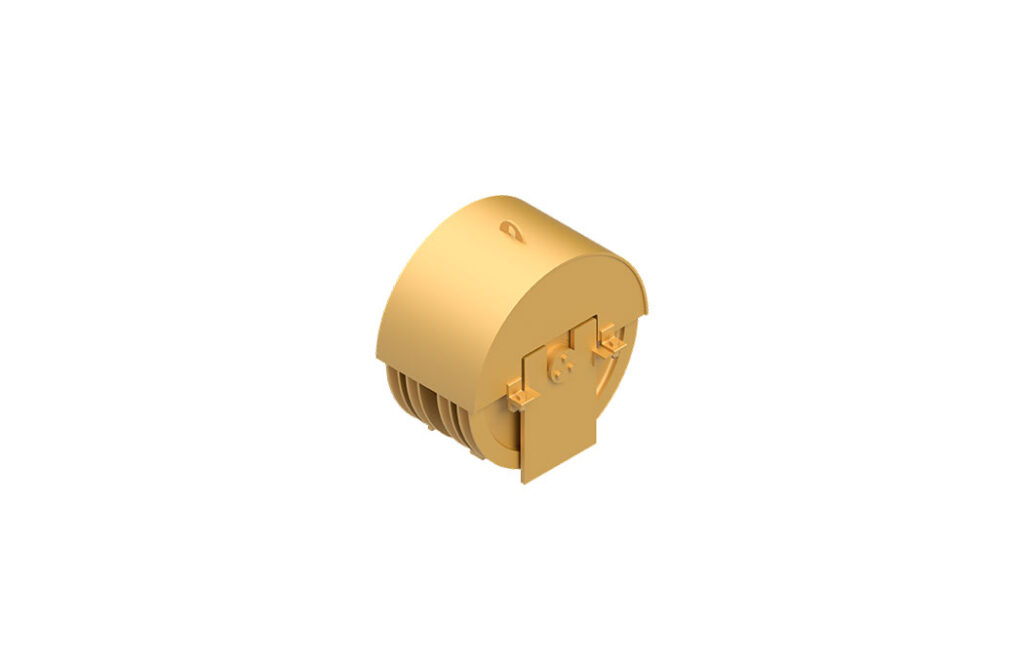

A digital rendering of a drum

Drum

The drum of an overhead hoist is a rotating, grooved cylinder for the wire rope to attach and accumulate onto. The diameter and length of the drum depend on the amount of rope needed to achieve the lift height required.

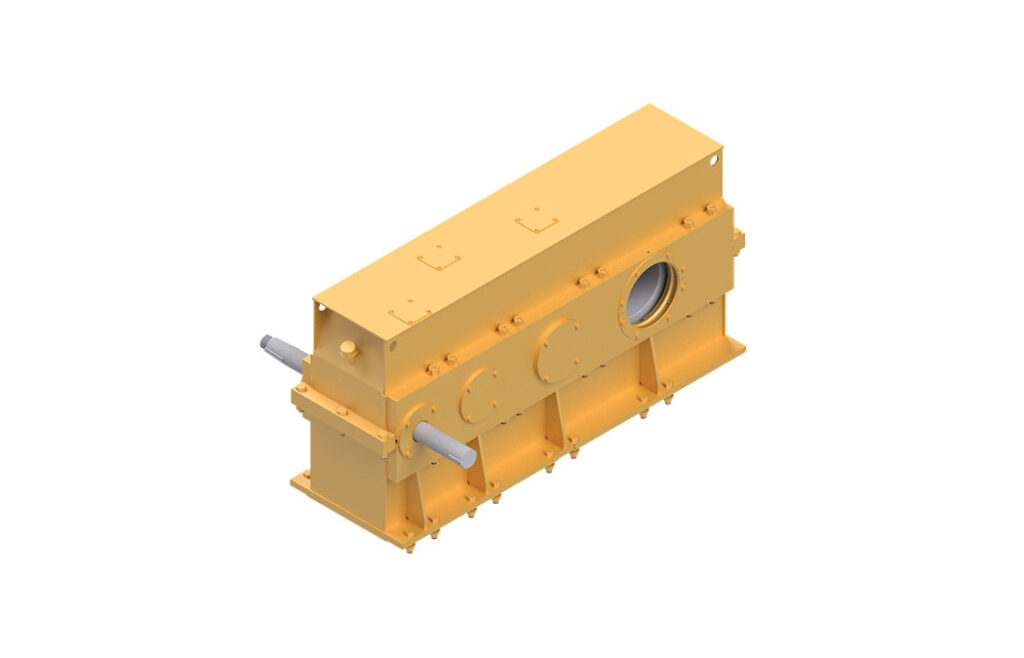

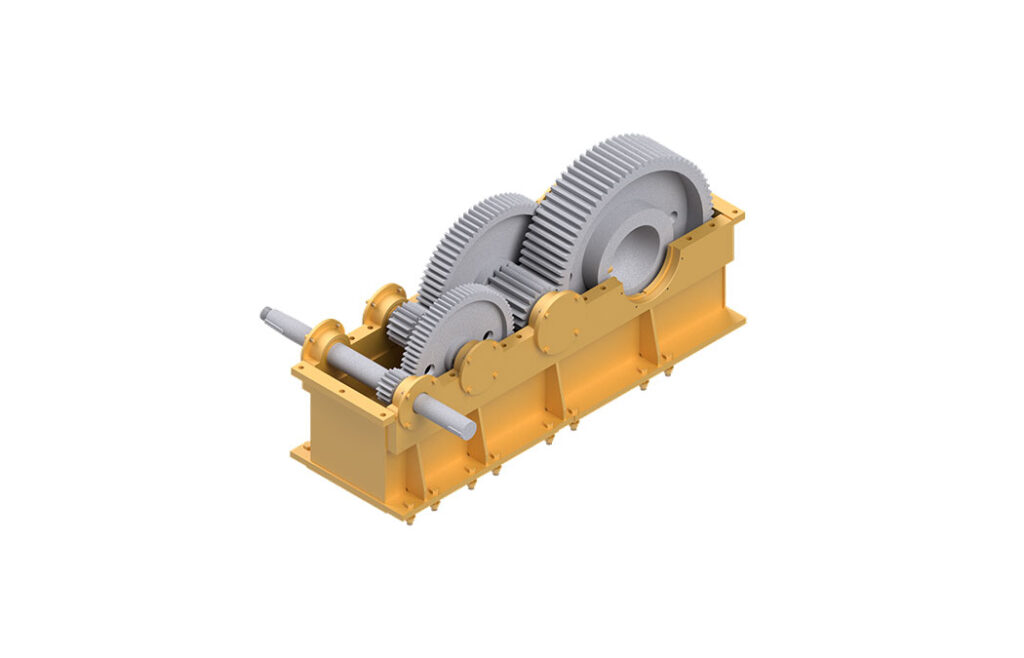

These images show a gearbox closed and what it looks like with the gears exposed.

Gearbox

A gearbox for an overhead hoist has a similar purpose to the one that drives the trolley wheels. It allows the trolley to move or, when connected to a drum, a load to be lifted. The combination of pinions and gears of various sizes that are mounted to the shafts and bearings, along with the reeving system, can be used to control the speed at which the hoist moves.

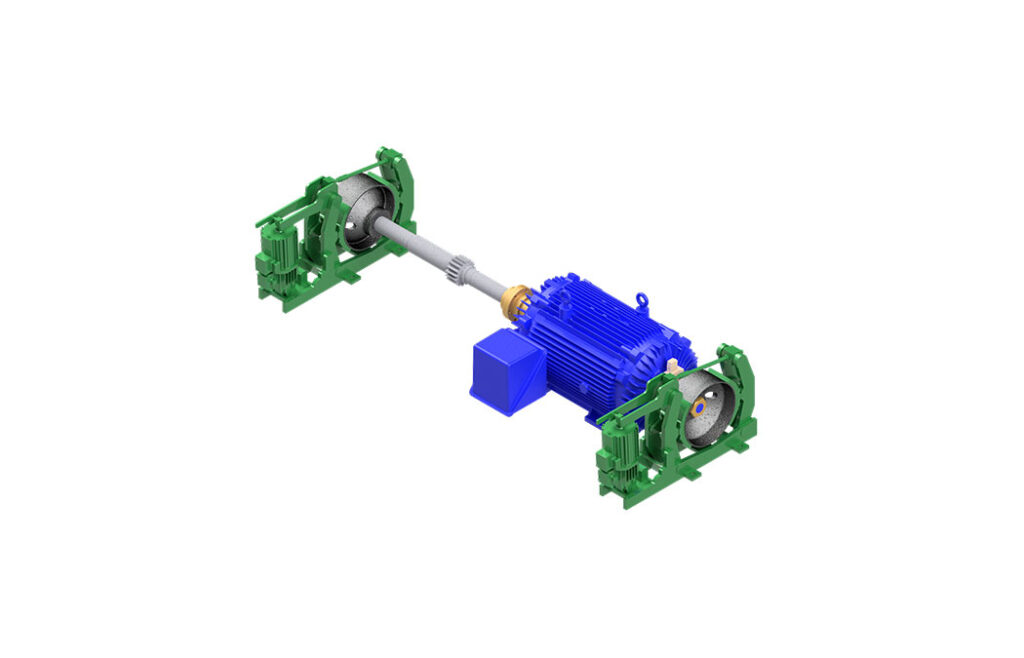

This rendering displays a motor and brake system.

Motor and Brake

The motor and brake work together to move and stop a load. The motor can move the hoist at various speeds as controlled by the overhead hoist system’s programming. Brakes are available in disc and drum configurations.

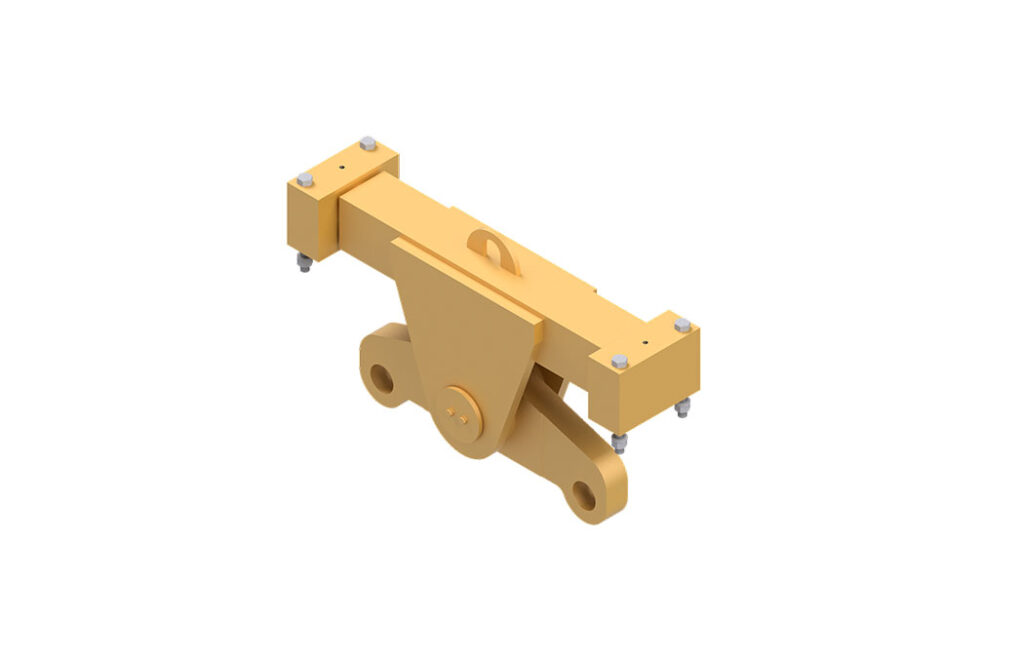

Hook Block/Lower Beam

A typical hook block frame will house the lower sheaves and hook mounting. Lower beam frames will house the sheaves and have multiple hooks, magnets, or grabs mounted to them depending on the application of the overhead crane.

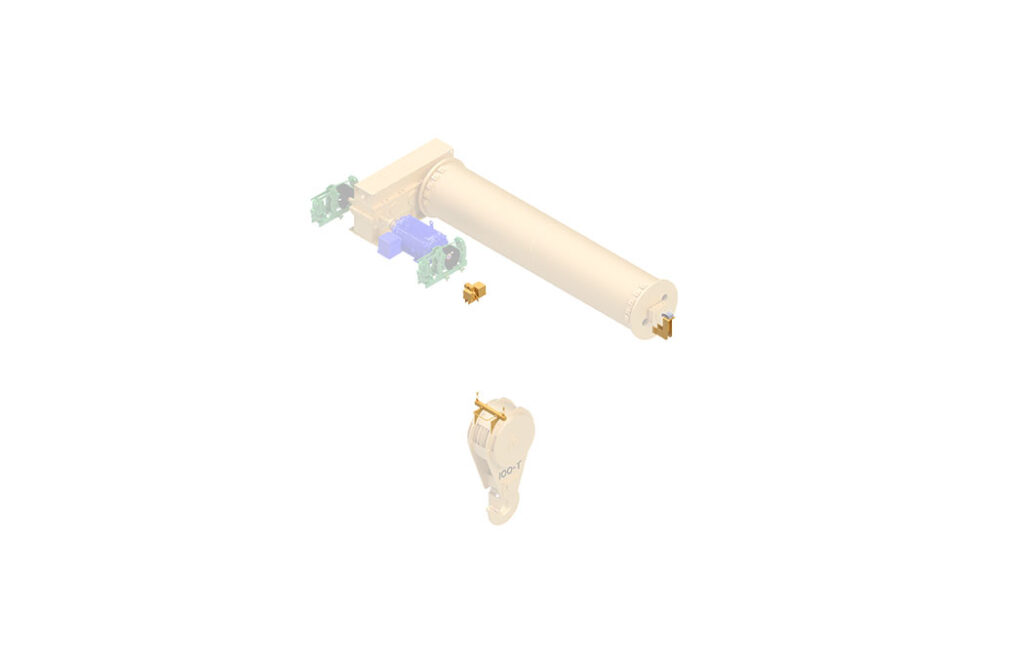

This image shows a limit switch and rotary limit.

Limit Switch and Rotary Limit

A limit switch is mounted on the deck of the trolley next to the equalizer or dead end. A weight is tripped by the hook block and tells the hoist when to stop raising. It serves as an excellent safety feature and the last line of defense to stop the load from damaging the trolley.

The rotary limit is mounted on the end of the drum and actively controls the high low positions of the load.

Here, a weigh system is shown as a digital rendering.

Weigh Systems

Weigh systems are an additional safety measure that can be incorporated into a hoist’s reeving system. A set of load cells is used on the upper sheaves and is calibrated to give an accurate reading of the weight of the load. This allows the crane operator to ensure they aren’t exceeding the crane’s capacity.

Custom Engineering from Concept to Crane

At Morgan Engineering, we combine our extensive experience with innovative crane technology to deliver custom-engineered overhead crane systems. If you’re interested in developing an overhead crane hoist or any other industrial overhead crane, contact us today.

Follow Morgan Engineering on social media for the latest updates in our Overhead Cranes Explained series. Find us on Facebook, LinkedIn, X (formerly Twitter), YouTube, and Instagram.