How to Reeve a Hook Block

/ Blog

Whether your business operates a crane rated for 25 tons or 500 tons, the crane hook block is a critical component of any material handling system.

But during maintenance and repairs – such as replacing your crane’s wire rope – it’s often necessary to remove the hook block while the crane is serviced. Before the crane can return to normal operation, the cable must be properly reeved through the hook block and reattached to the drum.

For maintenance tasks such as these, many customers call our team at Morgan Site Services to handle the job for them. But if you’re interested in reeving a hook block on your own, here’s a basic overview of some best practices to help protect your people and equipment in the process.

Step 1: Staging

As you get started, be sure to have all the people, equipment and materials needed to finish the job. Before reeving a hook block, the crane must be fully assembled and operational so the hoist motors can run and spin the gearing. Your hook block should be sitting vertically on a stand in the same position it will hang on the hoist cable. If replacing the wire rope, you’ll need a spool of cable brought over on a rack, and a man lift will be needed to position the cable. Keep in mind that this process can take anywhere from a few hours to all day, depending on the complexity of your crane, and may require up to 10 people.

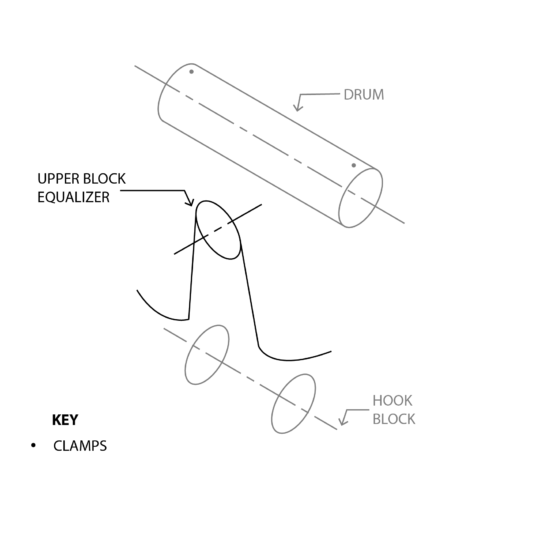

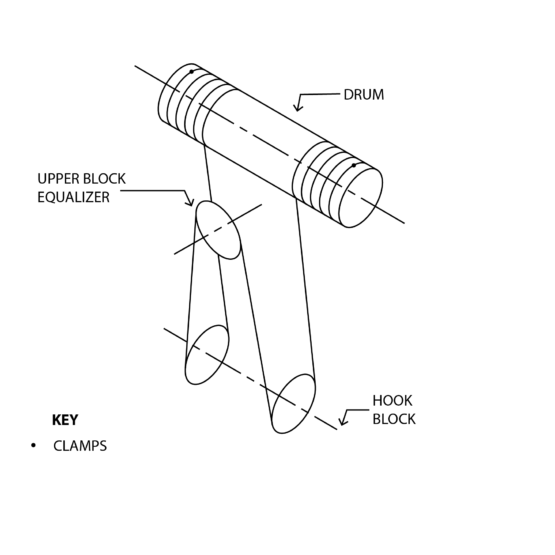

Step 2: Run the cable through the upper block equalizer

Now that you have your materials, you’ll begin by running the crane’s wire rope through the upper block equalizer sheave. How you accomplish this step will depend on the diameter of cable your crane requires. For smaller gauge cable, it’s possible to pull the cable over and through the upper block equalizer by hand using a man lift. However, for heavier gauge cable, it’s often necessary to run the cable using a nylon rope. For this method, you tie the rope to the end of the cable and run the rope through the upper block equalizer sheave. This rope can then be used to pull the cable through the upper block equalizer using the crane’s power.

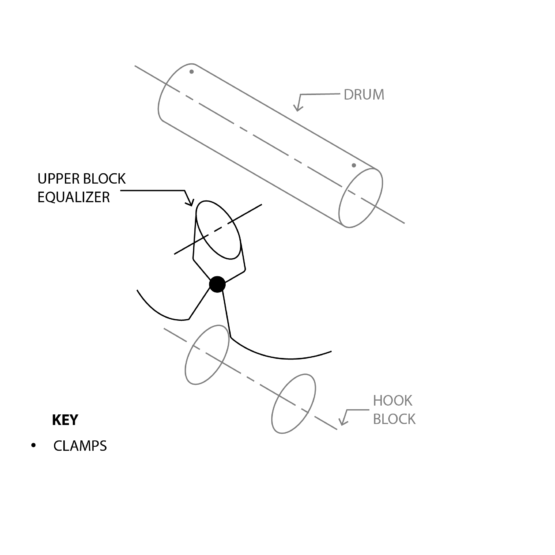

Step 3: Tie the cable

After the wire rope is pulled through the upper block equalizer, make sure that there’s an equal length of cable hanging from each side of the sheave. Then, use a crosby clamp or other type of wire rope clip to temporarily join both sides of the cable together near the upper block equalizer sheave. This step helps to ensure that the cable stays in position and nothing comes loose while reeving the hook block.

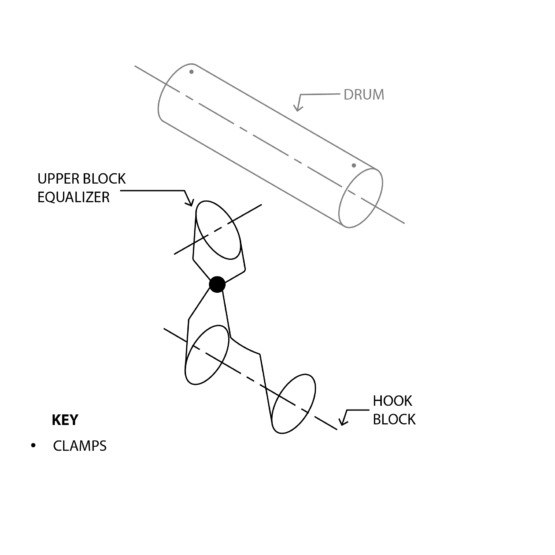

Step 4: Start reeving the hook block

Now, it’s time to start reeving one side of the cable through the sheaves in your hook block. Morgan offers a wide range of hook block styles and configurations, so be sure to follow the reeving instructions for your exact piece of equipment. It’s also important to note that incorrect cable routing is one of the most common mistakes made when reeving a hook block. If a reeving mistake is made at this stage of the process, all further work will need to be undone to correct the issue before operation. This reeving diagram provides instructions for many common Morgan hook blocks. However, if you have any questions about your specific application, contact a member of the Morgan Site Services team.

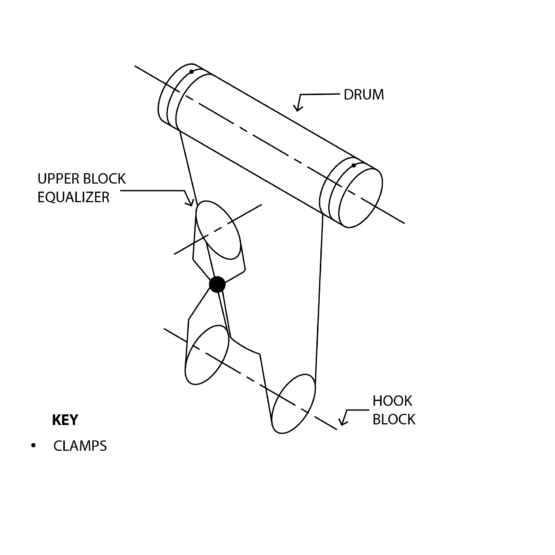

Step 5: Attach the cable to the drum

With one side of your wire rope correctly reeved through the hook block, it’s time to attach the cable to the crane’s hoist drum. To accomplish this, we recommend clamping your cable to the man lift, ensuring there’s a 15 to 20 ft. loop of cable hanging from the end of your clamping point. This allows you to lift the cable end to the drum using the man lift. Once an operator is at the drum, the loose end of the cable should be wrapped around the drum 1.5 to 2 times before it is clamped at the end of the drum. Wrapping the cable around the drum prevents all of the cable weight from hanging off your drum clamps. Wrap the cable starting from the inside of the drum, working to the outside edge. Then, tighten all cable clamps to the manufacturer’s specifications for your crane.

Step 6: Repeat steps 4 and 5

With one side of your cable attached to the drum, repeat the process for the other side. Follow steps 4 and 5 above, paying particular attention to the routing of the cable through the hook block sheaves.

Step 7: Hoist the hook block

At this point, the hook block reeving process is nearly complete. Slowly hoist the lift to take up slack in the line. As the drum is turned, it’s helpful to have several people watching different points of the crane to ensure that the cable is moving smoothly and does not get twisted. Pay particular attention to the drum, making sure the wire rope is wrapped properly and falls into the correct grooves. You should also confirm that the wire is routed correctly and moving smoothly through the hook block and upper block equalizer sheaves.

Keep your crane running safely and reliably

By following the steps outlined above, you can help ensure your crane will function properly – while avoiding potential component damage during the reeving process. But if you’d rather leave the job to the crane experts, call Morgan Site Services. Our team has the in-depth knowledge to quickly address your maintenance and repair issues. And unlike other crane maintenance companies, Morgan Site Services has the backing of a full-service engineering department.

When you choose Morgan Site Services, peace of mind comes standard. Peace of mind knowing that your job was done right — the first time; that your problems will be solved quickly and completely; and that your equipment will operate safely and reliably when we’re through.