How Many Spare Crane Parts Do You Need?

/ Blog

Maintaining a stockpile of spare parts for your overhead crane is critical to safeguarding production. The simple fact is, having the right spares on hand prevents the failure of a single part from halting production—potentially for months if the wrong part fails.

So, how do you know if you have enough spare overhead crane parts? The exact number will vary from crane to crane and mill to mill, but in general, you should always have enough spares to prevent your downtime from being equivalent to the time it will take a replacement part to arrive from a manufacturer.

Figuring out the exact number of spares you need requires knowing the general life expectancy of your various parts and adjusting that expected lifetime according to what you know about the wear and tear of your own operation.

To stay in my wheelhouse, I’ll just be covering mechanical and structural spares. My counterpart in Morgan Automation, Steve Herron, will give insight into electrical spares in a future post.

Life Expectancy of Mechanical Crane Parts

To help you in determining what your exact number of necessary spare parts is, here are some of the most common mechanical spares, their general life expectancy, and some additional things to keep in mind when stocking them for your cranes.

Wheel assemblies should generally last 8-10 years, however, this can be affected by the rail and building alignment of your crane. Track your wheel assembly wear by monitoring flange wear and the life of bearings. Keep in mind that wheel assemblies include both an idler and drive assembly; you’ll need to have both in stock as they aren’t interchangeable.

Gearing should generally last 8-10 years. Regularly inspect your gearing to ensure that it is not wearing faster than expected. Keep in mind that hoist gearing sometimes includes an opposite-hand assembly; you’ll need to have both in stock as they aren’t interchangeable.

Ropes should generally only last 1-2 years if used in severe duty service. In general service, you can expect 3-5 years.

Life Expectancy of Structural Crane Parts

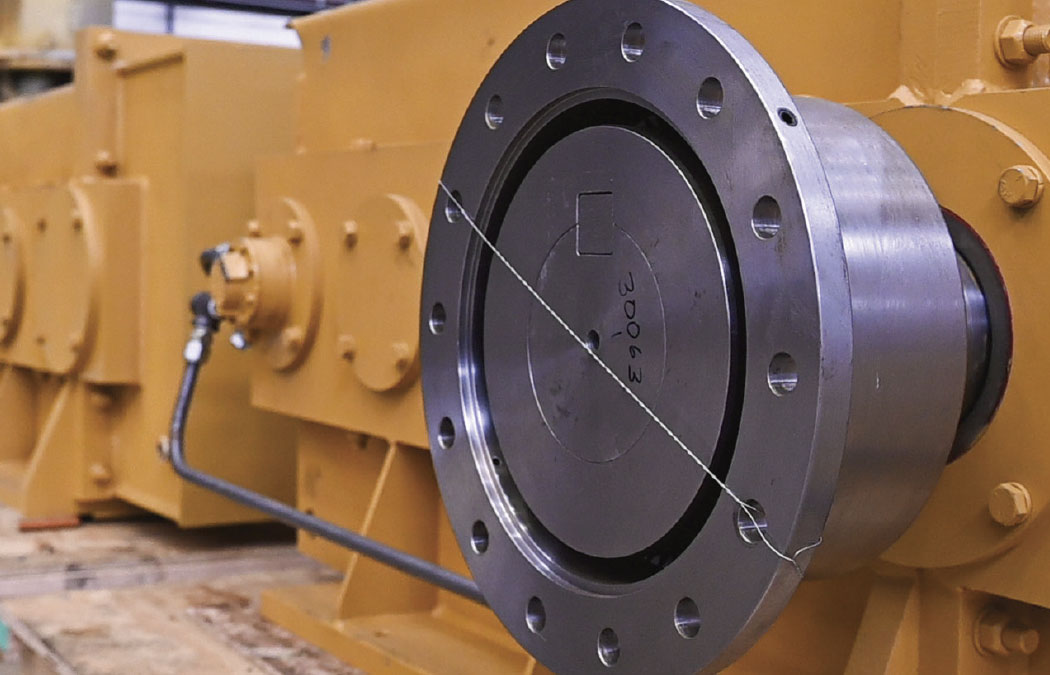

On the structural side of spare crane parts, drum, sheave, and hanger assemblies are some of the most critical spares to always have available.

Drums should generally last 10-20 years, depending on their service duty.

Hangers and laminated hooks have a recommended life of 5 years if they are used in severe duty service. Inspections are critical to ensure that hangers don’t fail unexpectedly before their recommended service life.

Sheaves and sheave assemblies should generally last 5-10 years. This includes pins, bearing, and any hook block. Just like hangers, regular inspections are critical to ensure that they don’t fail unexpectedly. Keep in mind that there are both upper and lower sheave assemblies; you’ll need to have both in stock as they aren’t interchangeable.

Crane Parts with Production in Mind

Based on these anticipated life cycles, you should have a set of spares on hand to keep your crane running when these parts are being thoroughly inspected and repaired. Most of these parts are considered repairable or rebuildable assemblies. When you switch them out with a spare, take them to a qualified inspection and repair shop to get them back into working order.

Ultimately, the basis of an informed stockpile of spare crane parts is a quality inspection program paired with experience in material handling equipment.

If you’re unsure if you have enough spare cane parts, Morgan offers comprehensive crane inspections and provides a list of recommended spares for every crane we design. We pack our spare parts for long-term storage, and when possible, design built-up assemblies that can be dropped into place for quick part replacement. Our expertise helps our customers with their material handling needs every day; I know we can help you too.