Piece by Piece: Overhead Cranes Explained – Part 2 – Trolleys

/ Blog

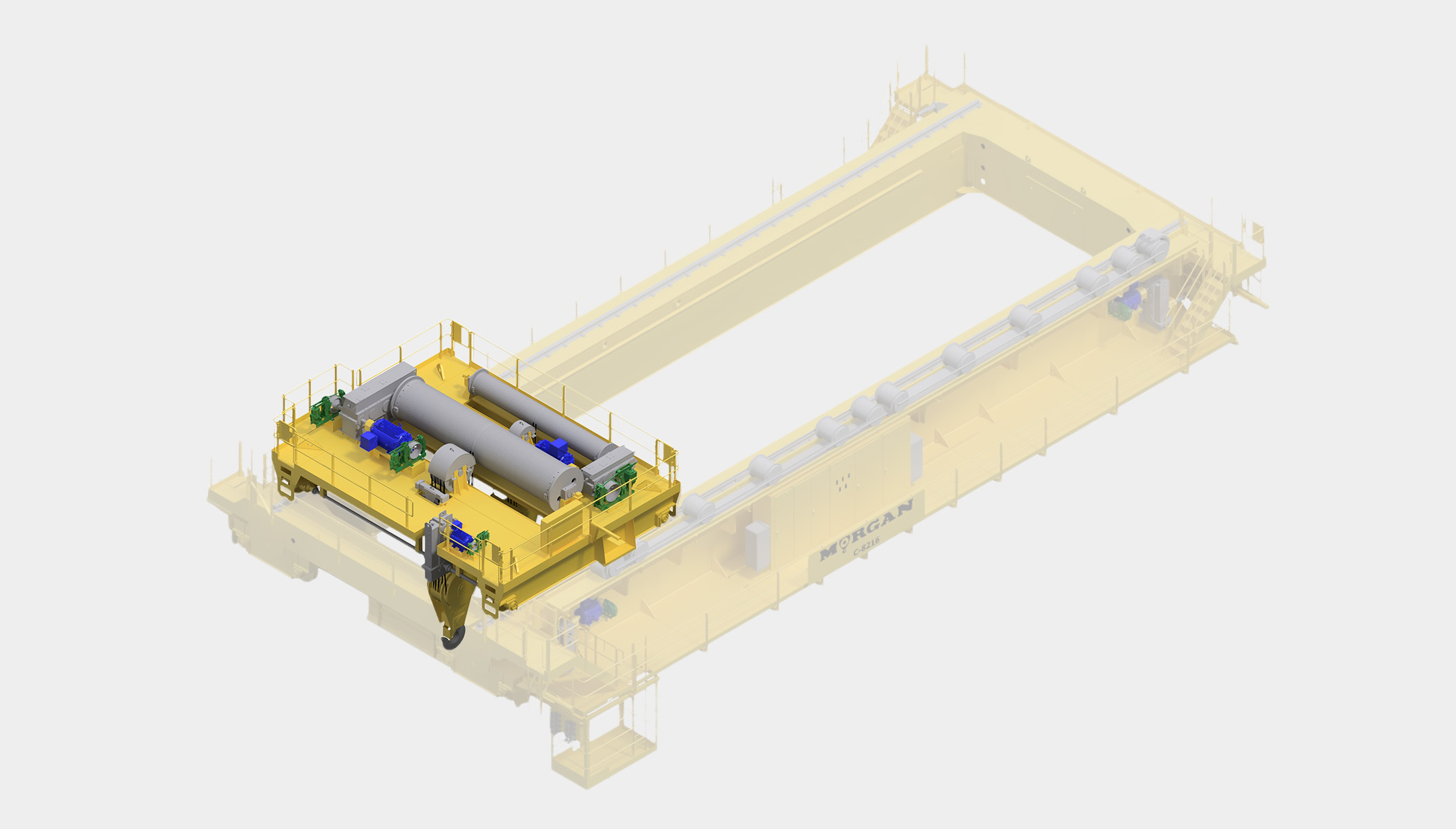

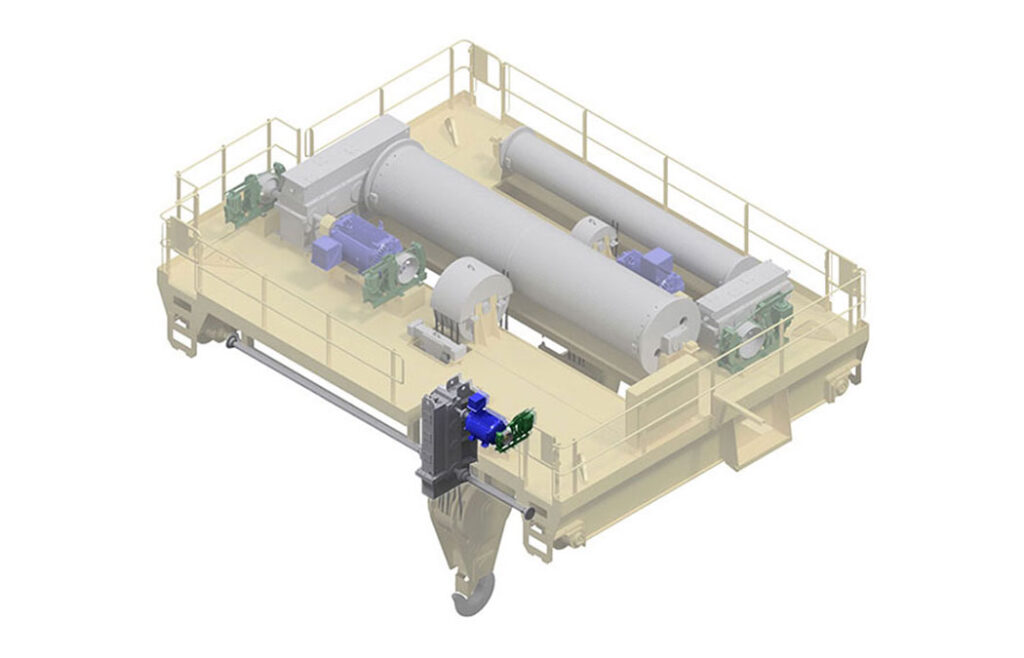

Overhead cranes are composed of about four main components: trolley, bridge, cab, and control house. Each of those four can be broken down further to help us understand how everything comes together. Today, our Piece by Piece series is looking at the trolley.

If you haven’t already, be sure to read Piece by Piece: Overhead Cranes Explained to get a bigger picture of overhead cranes.

A Trolley Defined

The overhead crane trolley is a pivotal system of components. It travels along the bridge, providing the initial horizontal movement. Trolleys can be customized to accommodate various hoists with different lifting capacities which gives a crane its vertical motion.

Based on the overhead crane’s application, the components on a crane trolley might vary, but the primary parts for its functioning remain consistent.

Main components of a trolley:

- Hoist

- Trolley Travel Assembly

- Frame

- Wheel Assembly

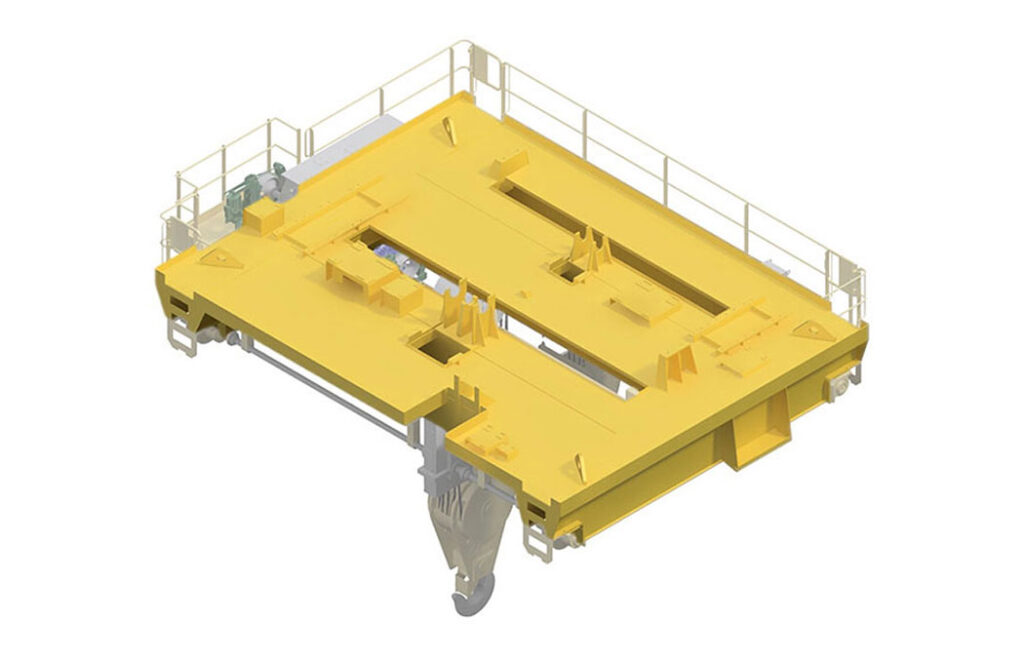

Frame: The Trolley’s Backbone

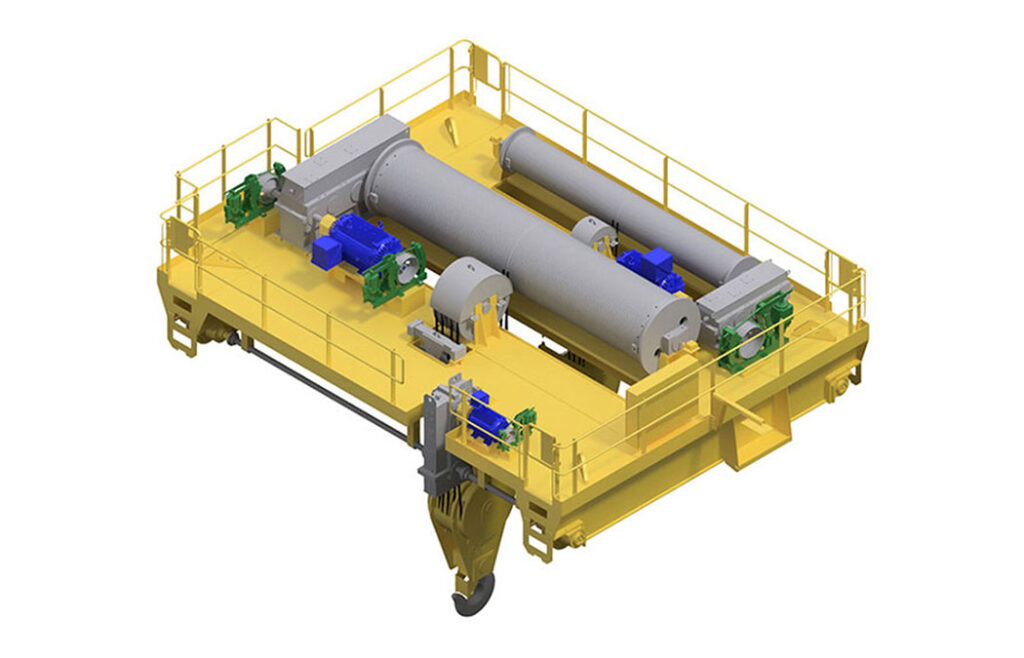

The crane’s trolley frame serves as the foundation for essential mechanical components. The trolley frame is a welded and machined structure. Its primary functions include:

- Providing a platform for the hoist

- Transferring the hoisting load to the wheel assemblies

- Being a mounting structure for the wheel assemblies, ensuring smooth guidance to the load path on the bridge rail

- Mounting travel mechanicals that connect to the driven wheel assemblies

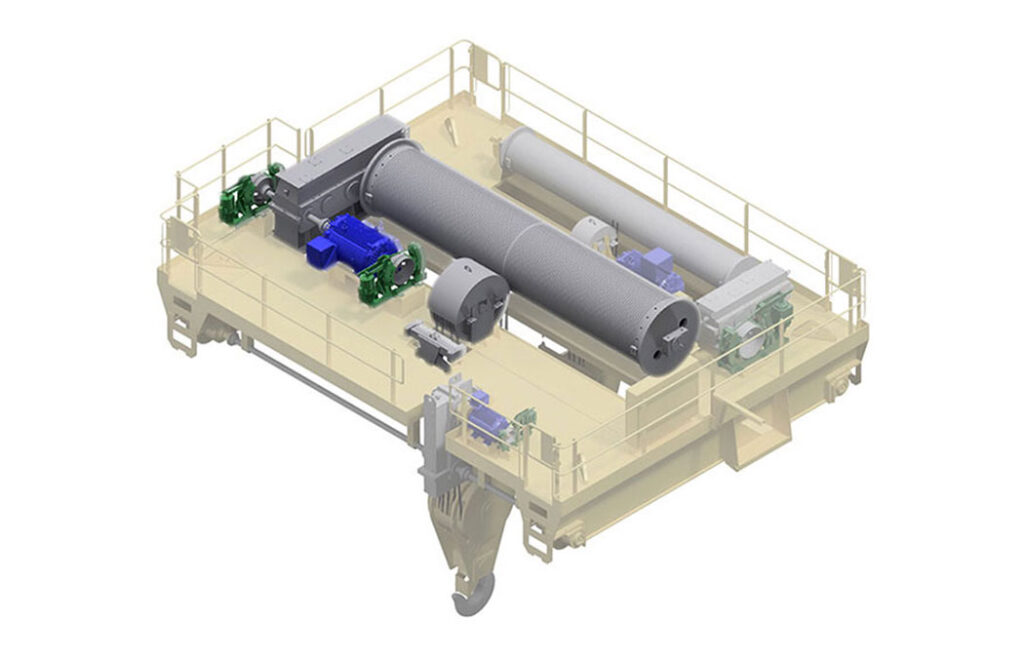

Hoist: The Power Behind Vertical Motion

The hoist’s mechanical equipment is mounted on top of the trolley’s frame and provides an overhead crane with its vertical motion. The hook assembly, reeved by means of wire rope, is designed for connection to the lifted load. The form of a trolley follows the necessary function of the hoist.

The trolley holds the hoist’s:

- Gearbox

- Motors

- Drum

- Brakes

- Upper Sheave Assembly

- Equalizer

- Hook Assembly

Trolley Travel Assembly: Navigating the Cross Travel

The trolley travel assembly is responsible for the trolley’s cross travel and is composed of the gearbox, a motor, line shaft, and brakes. These components of the overhead crane work in harmony to control the trolley’s speed allowing the crane operator to select from zero to full speed through precise controls.

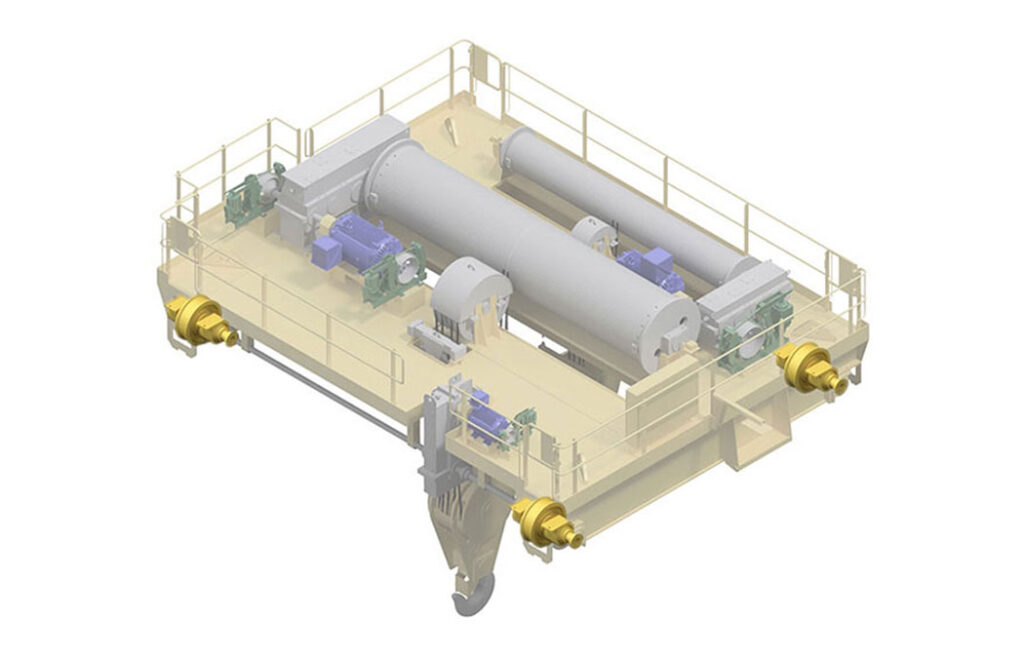

Wheel Assemblies

Housed by the frame, the wheel assemblies enable the trolley’s horizontal movement along the bridge rails. Typically, overhead bridge cranes feature trolleys equipped with four, six, or eight wheels. However, there can be any number of pairs of wheels on a trolley that come in different configurations. The wheels are driven in pairs on the frame to prevent skewing.

A crane’s trolley wheels closely resemble those of a train, they stay securely on course by fitting the tread and flange of the wheel on to the head of the rail.

Multiple pairs of wheels can be driven to provide the necessary effort to move the trolley. The wheels connected to the travel drives are identified as drive wheels. The wheel pairs that provide the additional load support, but are not connected to a travel drive, are identified as idler wheel assemblies.

Customizable Trolleys: Tailored for Specific Needs

Trolleys come in various sizes, ranging from the size of a car to the size of a small house, depending on the overhead crane’s lifting capacity and application. The number of hooks, hook attachments, and lifting capacities must be considered.

Additional safety features such as handrails, hoist speed control, and weigh systems, can be incorporated. In rare cases, trolleys can rotate, providing crane operators with the ability to adjust the hoist’s position as needed.

Stiff leg trolleys, as seen in the picture above, offer enhanced stability by giving the hook block a surface to brace against and eliminating swaying of the load. These trolleys are used where the crane is moving very quickly, and the accurate position of the load is crucial. These trolleys find use in specialized applications like coil yard cranes.

The trolley’s custom design ensures optimal crane performance, making it a vital component in overhead crane systems.

Customize a Crane for Your Company

Now that you have learned the 4 main components of a trolley: hoist, trolley travel assembly, frame, and wheel assembly, make sure to follow along as we tackle the main components that make up a bridge in our next Piece by Piece series.

Ready to elevate your lifting capabilities to new heights? Contact us to discuss how Morgan can custom engineer a crane solution that perfectly suits your unique needs.